Honle UV LED Power Pen 2.0 for UV Adhesive Curing

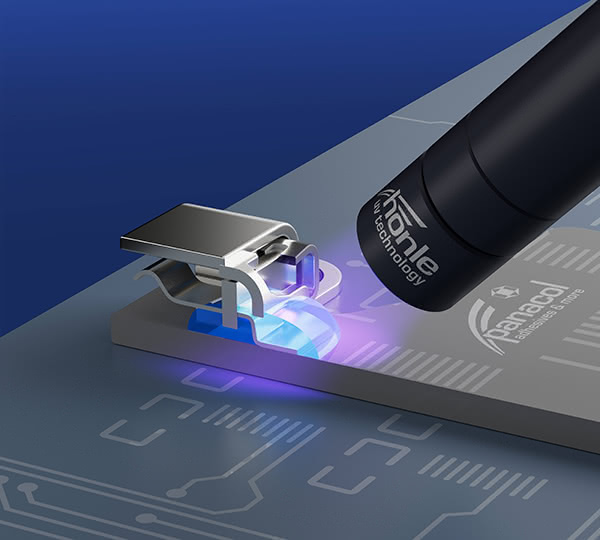

When to Use the Honle LED Power Pen 2.0The Honle LED Power Pen 2.0 is a simple but powerful UV curing device allows for high intensity UV curing using LED light technology. This system excels when applying and curing adhesives to heat sensitive substrates and where maneuverability is key. There are 365nm and 405nm wavelengths available to match adhesive curing needs. Available with foot pedal option for hands free use.LED Power Pen 2.0 Common Applications Bonding and fixing components in medical and electronics Fluorescent excitation for material testing High intensity UV irradiation for biological, chemical and pharmaceutical industries DetailsThe Honle LED Power Pen 2.0 offers a number of advantages over traditional UV bulk curing systems. This LED pen offers less heat impact, zero start up time and does not emit IR radiation. This makes the LED Power Pen safer and more

is on a mission to simplify the fluid and adhesive dispensing buying process. Shop easily configurable pump, vacuum and manual dispensing systems, industrial adhesives and accessories for all of your fluid and adhesive dispensing needs.

When to Use the Honle LED Power Pen 2.0The Honle LED Power Pen 2.0 is a simple but powerful UV curing device allows for high intensity UV curing using LED light technology. This system excels when applying and curing adhesives to heat sensitive substrates and where maneuverability is key. There are 365nm and 405nm wavelengths available to match adhesive curing needs. Available with foot pedal option for hands free use.LED Power Pen 2.0 Common Applications

Bonding and fixing components in medical and electronics

Fluorescent excitation for material testing

High intensity UV irradiation for biological, chemical and pharmaceutical industries

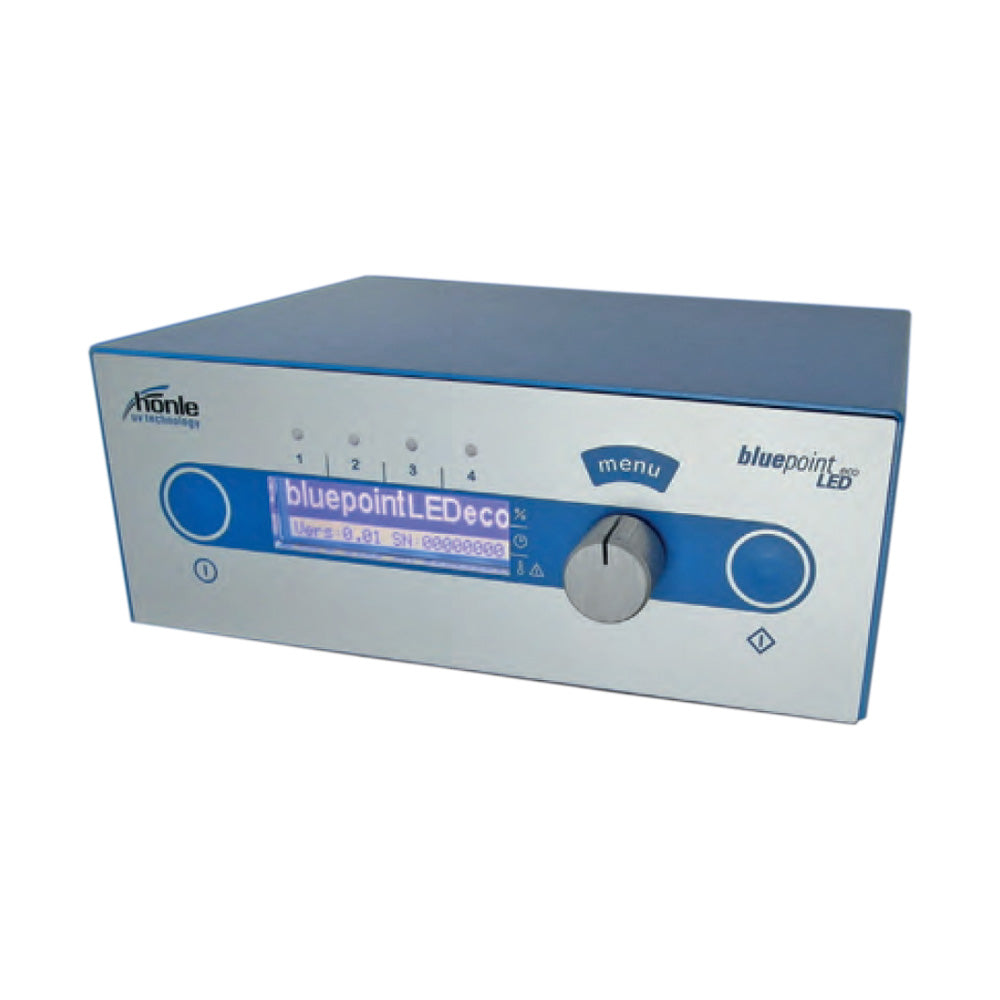

DetailsThe Honle LED Power Pen 2.0 offers a number of advantages over traditional UV bulk curing systems. This LED pen offers less heat impact, zero start up time and does not emit IR radiation. This makes the LED Power Pen safer and more convenient for many UV adhesive bonding applications. Advantages of LED Pen TechnologyThe use of LED devices offers the following advantages: LED’s do not emit IR radiation. With reduced heat output the processing of almost all heat sensitive materials is possible. The monochromatic spectrum of the LED Power Pen matches the absorption of photo-initiators in UV curable adhesives and allows a fast and efficient cure. The LED Power Pen can be switched on and off as often as necessary. He does not require a warm-up or cooling phase.Advantages of LED Pen Technology in UV CuringThis LED pen offers a compact size and low weight so it can be used in hard to reach areas. The LED Power Pen is powered via an external plug-in supply unit (adaptable for the world wide use) which is included in the scope of delivery. The LED Power Pen is manually operated by using a pressure switch on the unit.Specifications

Peak wavelength

365/405 nm +/- 10 nm

UVA Intensity in 12 mm distance*

10.000 mW/cm² at 365 nm

16.000 mW/cm² at 405 nm

Electrical power input

ca. 5 W

Mains supply

From external net 100-240V AC

Dimensions (Ø x length)

26 mm x 140,5 mm

Weight

140 g

Continuous operation

without additional cooling

max. 10 minutes

ResourcesProduct Data SheetContact Us for Data Sheets

Honle Bluepoint LED Eco UV Adhesive Light Curing System

UVA Cube 400

LED Power Pen 2.0

UV and LED-UV devices and systems by Dr. Hönle AG

Bonding / potting & sealing

Hoenle-UV Photo Source Equipment - About Ezbond Chemical Co., Ltd.

Honle and Panacol-USA, Inc.

Hoenle UV Technology (UV Curing System) – Axend

When to Use the Honle LED Power Pen 2.0The Honle LED Power Pen 2.0 is a simple but powerful UV curing device allows for high intensity UV curing using

Honle UV LED Power Pen 2.0 for UV Adhesive Curing

Techsil Hoenle UVACube 2000 UV Light Curing Chamber Kit

UV LED Dr. Hönle AG expert in uv technology

UV+EB Technology - 2020 Quarter 2 by petersonpublications - Issuu