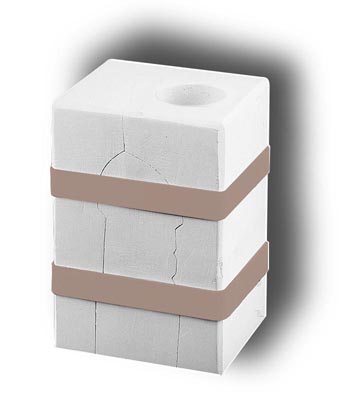

Ceramic molds prepared after firing at 800ºC, 900ºC, 1000ºC and 1080ºC

Download scientific diagram | Ceramic molds prepared after firing at 800ºC, 900ºC, 1000ºC and 1080ºC for the compressive strength test from publication: The Assessment of Clay Briquettes from East of Erbil City Northern Iraq for Utilization in Various Building Applications | Assessment of clay briquettes for various building applications take into consideration, for this purpose seven clay samples by channel method collected from Injana, Mukdadiya and Bai Hassan Formations with Quaternary deposits in Bestana village, for the evaluation test | Briquette, Cities and Bricks | ResearchGate, the professional network for scientists.

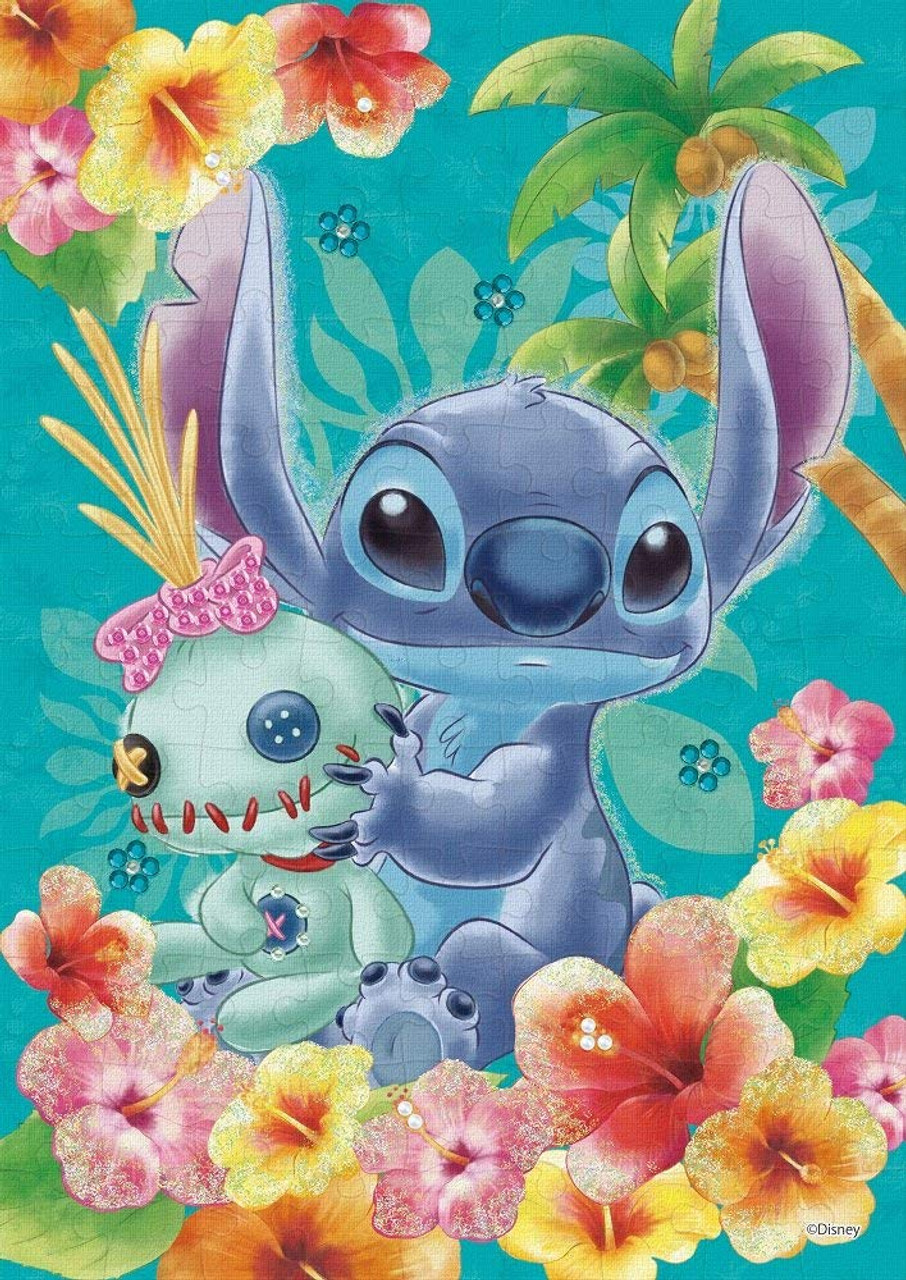

Mold Prep 101 - Using Boron Nitride

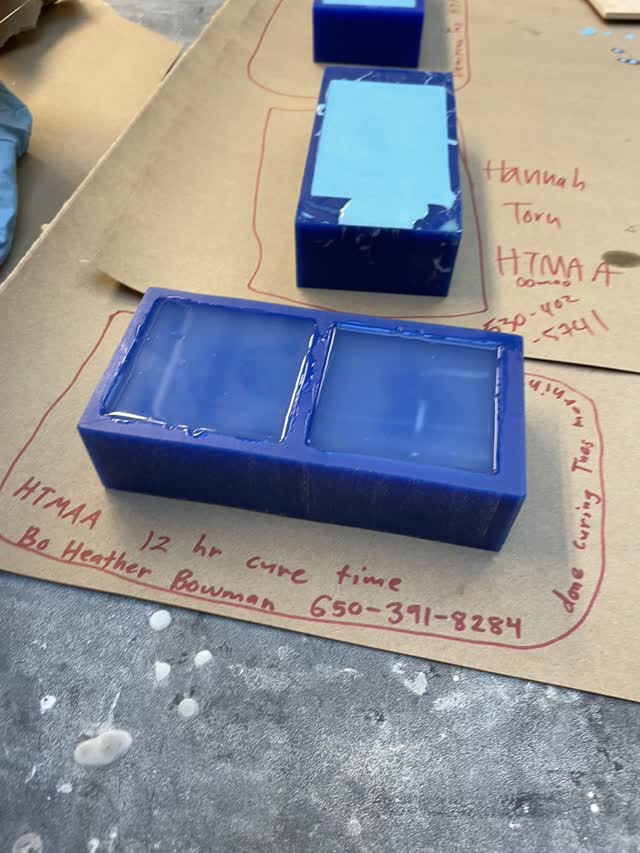

Week 8

Ceramic Mold - an overview

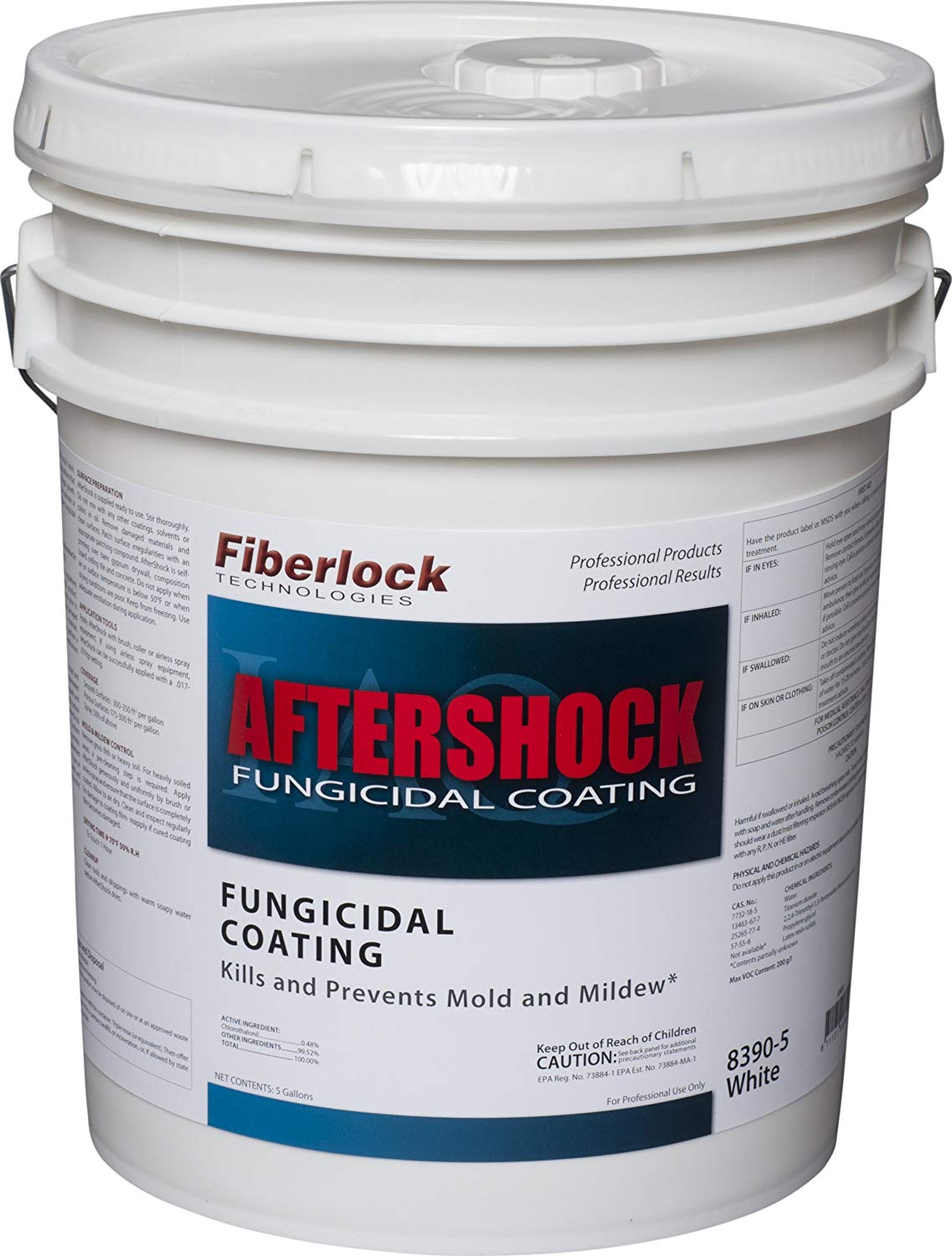

AfterShock 8390 5 Gallon fungicidal coating is EPA-registered and designed to kill tough residual mold and mildew while inhibiting future growth. 100%

AfterShock Mold Remediation - EPA Registered Fungicidal Coating (Five Gallon): 8390

Ceramic Mold - an overview

Mold Prep 101 - Using Boron Nitride

1700 Degree Laboratory Muffle Furnace with Ceramic Pottery Kiln

PDF) The Assessment of Clay Briquettes from East of Erbil City

This great ceramic slip mold shows signs of basic use. It does show signs of basic use on the outside with an external chip as shown.

SFA 642 Ceramic Slip Mold 7.75 Ruffle Top Ornate Handled Plain Pitcher

Fusing: How to Prepare a Mold Using Boron Nitride

Ceramic molds prepared after firing at 800ºC, 900ºC, 1000ºC and

AC3S50 : ACT, 1-1/8 x 3/8 - Angle Cut Tri-Star Ceramic, P-20 Fast Cut

Yick Sang(YS) to VDI Yick sang Vs Mold-Tech texture - Upmold

Jun (Chün) glaze tests: Reduction cooling (down firing) — HAMISH